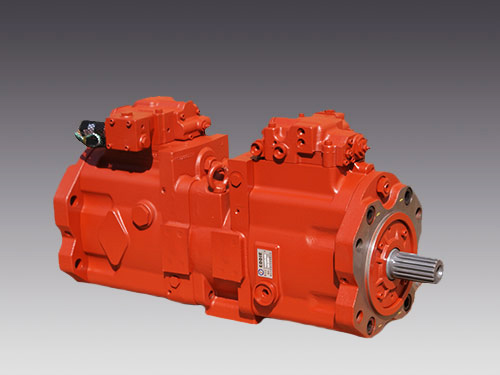

F3V140S Hydraulic Pump: Precision Power for Demanding Applications

Welcome to HydraulicElite.com, your trusted source for high-performance hydraulic solutions. We are proud to present the **F3V140S Hydraulic Pump**, a robust and reliable component engineered to deliver exceptional power and efficiency in the most challenging industrial and mobile environments. Designed for precision control and durability, this pump is an ideal choice for systems requiring consistent and powerful hydraulic pressure.

Product Overview: F3V140S Hydraulic Pump

The F3V140S is a variable displacement axial piston pump known for its high power density, excellent control characteristics, and long service life. Its advanced design ensures optimal performance, reduced energy consumption, and quieter operation, making it a valuable asset in a wide range of hydraulic systems. Whether you're upgrading an existing system or designing a new one, the F3V140S offers the reliability and efficiency you need.

Key Product Specifications

Model: F3V140S

Type: Axial Piston Variable Displacement Pump

Displacement: Typically around 140 cm³/rev (cubic centimeters per revolution) - *Exact displacement may vary slightly by specific model variant.*

Max. Operating Pressure: Designed for high-pressure applications, often exceeding 350 bar.

Speed Range: Wide operating speed range for versatile application.

Mounting: Standard mounting options for easy integration.

Control Options: Various control options available including pressure compensator, load sensing, and power limiting.

Fluid Compatibility: Compatible with a variety of hydraulic fluids, including mineral oils and synthetic fluids.

Outstanding Advantages & Selling Points

High Efficiency: Minimized power loss thanks to advanced design, leading to lower operating costs and reduced heat generation.

Robust Construction: Built with high-quality materials and precision engineering to withstand harsh operating conditions and ensure extended lifespan.

Precise Control: Excellent responsiveness and accurate flow control, enabling precise machine movements and enhanced operational safety.

Low Noise Level: Engineered for quieter operation, contributing to a more comfortable and compliant working environment.

Versatile Applications: Adaptable to a broad spectrum of hydraulic systems due to its variable displacement and control options.

Easy Maintenance: Designed for straightforward servicing, minimizing downtime and maximizing productivity.

Ideal Equipment Applications

The F3V140S Hydraulic Pump is an excellent fit for heavy-duty machinery and industrial equipment that demand reliable and powerful hydraulic performance. Its versatility makes it suitable for:

Construction Equipment: Excavators, wheel loaders, bulldozers, concrete pumps, road pavers.

Mining Machinery: Drills, rock crushers, large-scale conveyors.

Agricultural Machinery: High-power tractors, combine harvesters, large-scale spraying equipment.

Marine Applications: Fishing vessels, tugboats, offshore platforms (for winches, cranes, steering systems).

Industrial Presses: Metal forming presses, plastic injection molding machines.

Material Handling Equipment: Large forklifts, container handlers, reach stackers.

Application Scenarios & Case Studies

The F3V140S excels in scenarios where high power and precise control are critical. Here are some examples:

Excavator Boom and Arm Control: In large excavators, the F3V140S can power the main hydraulic circuits for boom, arm, and bucket movements. Its variable displacement ensures that the operator has precise control over digging and lifting operations, optimizing efficiency and safety on construction sites. For instance, an F3V140S pump deployed in a 30-ton excavator significantly improved its digging force and cycle times, leading to a 15% increase in daily output compared to a previous model.

Concrete Pump Boom Operation: For concrete pumps, the F3V140S provides the necessary power for extending and retracting the multi-section boom, as well as operating the concrete discharge. The precise flow control ensures smooth and accurate positioning of the boom, crucial for high-rise construction projects. A case study showed that a concrete pump equipped with the F3V140S experienced fewer system shocks and greater stability during boom extension, reducing wear on other components.

Large Agricultural Sprayers: In modern large-scale agricultural sprayers, the pump is vital for maintaining consistent spray pressure and flow across wide booms. The F3V140S can handle the demanding hydraulic loads, ensuring uniform application of chemicals over vast fields. A farm reported a 10% reduction in fuel consumption for their sprayer after upgrading to an F3V140S due to its superior efficiency.

Related & Similar Products

While the F3V140S is a top performer, we also offer other high-quality hydraulic pumps that might suit different specifications or applications:

F3V110S Hydraulic Pump: A slightly smaller displacement variant, ideal for mid-sized construction equipment (e.g., smaller excavators, compact loaders), municipal vehicles, and lighter industrial machinery where space or power requirements are slightly less stringent than the F3V140S.

F3V180S Hydraulic Pump: A larger displacement pump, perfect for very heavy-duty applications such as large mining trucks, massive port cranes, and highly demanding industrial presses that require even greater hydraulic power and flow.

Gear Pumps (e.g., G20 Series): While different in principle, gear pumps offer cost-effective and robust solutions for lower pressure or fixed displacement applications. They are commonly found in power steering systems, auxiliary circuits on mobile machinery, and simpler industrial hydraulic power units.

Vane Pumps (e.g., VQ Series): Known for their quiet operation and good efficiency at medium pressures, vane pumps are often used in industrial machinery like machine tools, plastics processing equipment, and certain agricultural implements where noise reduction is a priority.

Common Installation & Maintenance Issues and Solutions

Proper installation and regular maintenance are crucial for the longevity and optimal performance of your F3V140S hydraulic pump. Here are some common issues and their solutions:

Issue: Excessive Noise or Vibration

Cause: Often due to cavitation (air in the fluid), aeration (air leaking into the suction line), misalignment between pump and prime mover, or a clogged suction filter. Low fluid level can also cause air ingress.

Solution:

Check and maintain proper hydraulic fluid levels in the reservoir.

Inspect all suction line connections for leaks and ensure they are tight.

Clean or replace clogged suction filters.

Verify alignment of the pump and motor/engine; use flexible couplings if necessary.

Ensure correct fluid viscosity for operating temperature.

Issue: Overheating Hydraulic System

Cause: Can be caused by fluid contamination, low fluid level, clogged cooler, internal leakage within the pump or system components, or incorrect relief valve settings.

Solution:

Monitor fluid temperature and ensure it stays within the recommended range.

Regularly check and replace hydraulic fluid according to manufacturer specifications; ensure it's free of contamination.

Clean or clear obstructions from the hydraulic cooler.

Investigate system for internal leaks (e.g., worn cylinder seals, faulty valves).

Verify relief valve settings are correct and not causing excessive bypassing.

Issue: Loss of Pressure or Erratic Operation

Cause: Often due to worn pump internals, faulty relief valve, internal system leaks, or air in the system.

Solution:

Check pressure gauge readings for anomalies.

Inspect the relief valve for proper function and adjustment.

Look for signs of external leaks and address them immediately.

If no external leaks, internal components (pump, cylinders, valves) may need inspection or repair.

Bleed air from the system if suspected.

Issue: Fluid Contamination

Cause: Inadequate filtration, poor fluid handling practices, or ingression from worn seals and breathers. Water and particulate matter are common contaminants.

Solution:

Implement a strict filtration schedule; regularly change filters.

Use high-quality hydraulic fluid and store it properly.

Ensure reservoir breathers are clean and functioning.

Regularly analyze fluid samples to detect contamination early.

Maintain clean working environment during fluid changes or component replacement.

For detailed troubleshooting or specific technical inquiries, please do not hesitate to contact our technical support team. We are committed to providing you with the best hydraulic solutions and support.

English

English português

português Français

Français